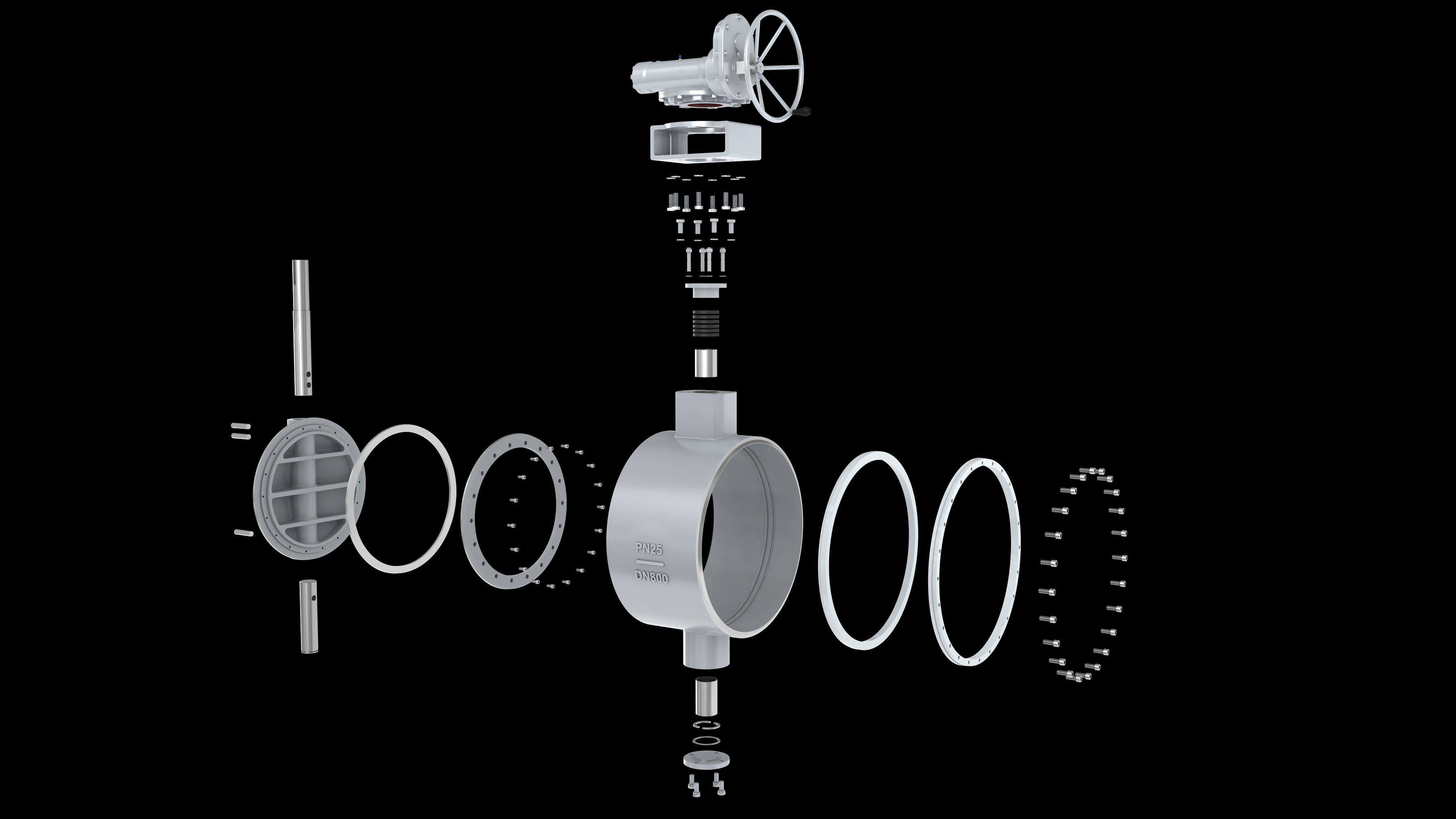

Butt Welding Cast Steel Body Hard Seal Butterfly Valve

Size: 6″~80″(DN150~DN2000)

Pressure: ASME CLASS 150~600(PN16~PN100)

Body Materials: Carbon Steel, Stainless Steel, Alloy Steel and Duplex Steel

concatenon: Butt welding

Mode of operation : Worm gear , electric, pneumatic, hydraulic,Handle

Product Usage

Three eccentric two-way metal seal welding butterfly valve is widely used in water conservancy projects, water, electricity circulating water, oil, chemicals and other industrial pipe for cutting off the flow of media.

Features

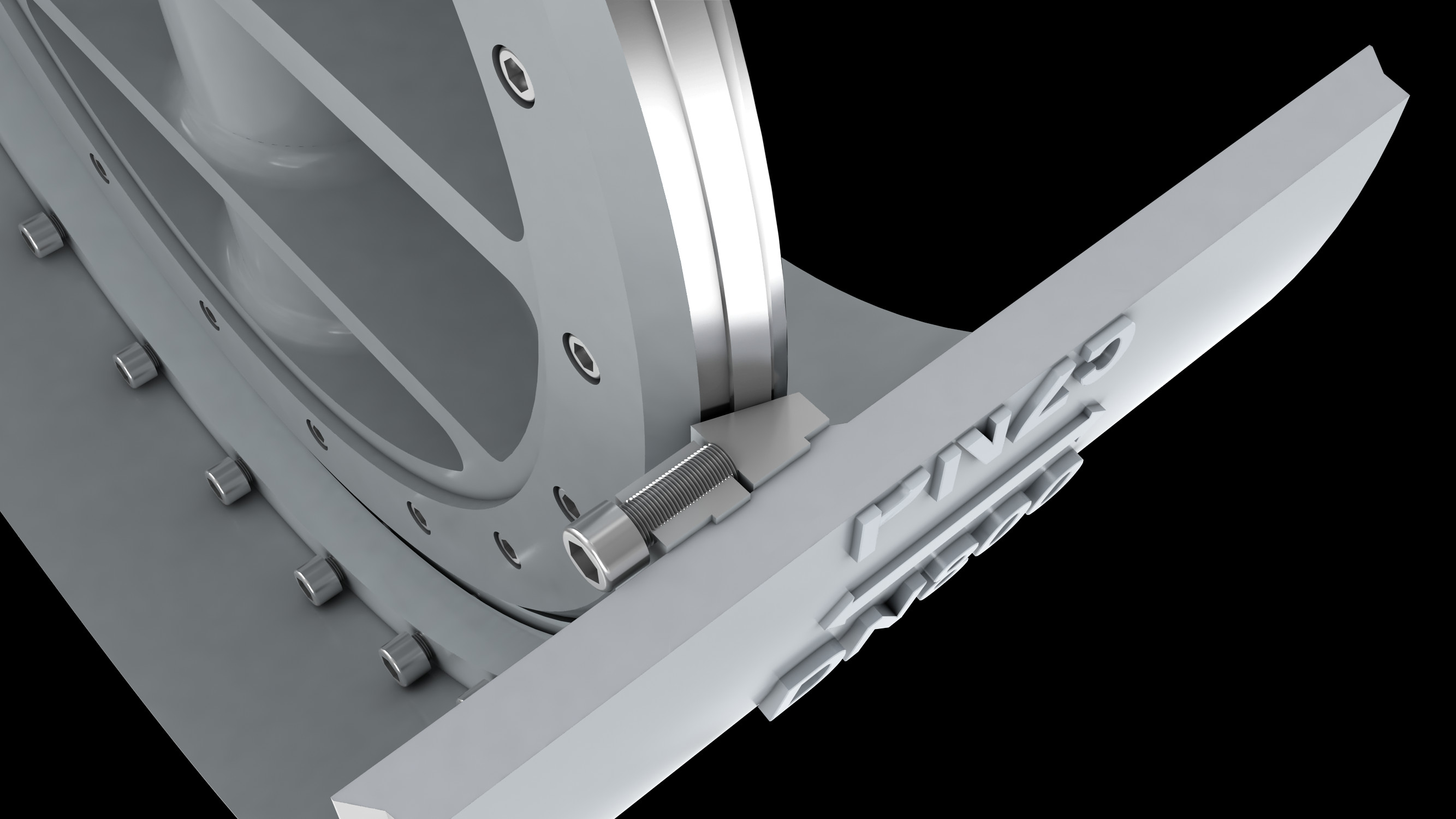

1. The butterfly valve is bi-directional pressure, two-way metal seal, a special structure can be adjusted seal than the pressure, the use of eccentric S-shaped seat sealing surface, so that the sealing surface is not easy to damage and improve the service life of the valve.

2. Smaller operating torque, turn 90 degrees opening and closing, light and rapid.

3. The flow resistance is small, with good hydraulic characteristics, the flow characteristics of a straight line inclined, energy-saving effect, two-way seal on the water without direction.

4. Reliable sealing, opening and closing life of more than 25,000 times.

5. The valve plate with dual-plate truss-type multi-runner design in line with fluid mechanics.

Executive Standard

Design and manufacture of standards: GB / T 12238-2008, JB / T8527-1997

Structure length standard: GB / T 12221-2005

Connection flange standard: GB / T 9113

Pressure temperature grade: GB / T 12224-2005

Test test standards: GB / T 13927-2008

.jpg)

| Model | D363H-10 | D363H-10P | D363H-10R | |

| D363H-16 | D363H-16P | D363H-16R | ||

| D363H-25 | D363H-25P | D363H-25R | ||

| D363H-40 | D363H-40P | D363H-40R | ||

| Work pressure(MPa) | 1.0~4.0 | |||

| Proper temperature(℃) | ≤425 | ≤200 | ||

| Applicable medium | water, oil or non-corrosive media | Nitric acid medium | Acetic medium | |

| Material | Valve body, butterfly plate | WCB | CF8/304 | CF3M/316L |

| Stem | 2Cr13 | 304 | 316L | |

| Body sealing surface | Surfacing 507 | - | - | |

| Butterfly plate sealing surface | 304+Flexible graphite | 304+PTFE | 304+PTFE | |

| Filler | Flexible graphite | PTFE | PTFE | |

|

DN(mm) |

L |

1.0MPa |

1.6MPa |

||

|

H1 |

H |

H1 |

H |

||

|

100 |

190 |

280 |

390 |

280 |

390 |

|

125 |

200 |

300 |

420 |

300 |

420 |

|

150 |

210 |

320 |

460 |

320 |

460 |

|

200 |

230 |

370 |

550 |

370 |

550 |

|

250 |

250 |

420 |

620 |

420 |

620 |

|

300 |

270 |

500 |

750 |

500 |

750 |

|

350 |

290 |

530 |

800 |

530 |

800 |

|

400 |

310 |

570 |

870 |

570 |

870 |

|

450 |

330 |

600 |

920 |

600 |

920 |

|

500 |

350 |

680 |

1040 |

680 |

1040 |

|

600 |

390 |

750 |

1190 |

750 |

1190 |

|

700 |

430 |

810 |

1290 |

810 |

1290 |

|

800 |

470 |

905 |

1440 |

905 |

1440 |

|

900 |

510 |

960 |

1550 |

960 |

1550 |

|

1000 |

550 |

1010 |

1650 |

1010 |

1650 |

|

1200 |

630 |

1175 |

1920 |

1175 |

1920 |

|

1400 |

710 |

1310 |

2170 |

1310 |

2170 |

|

1600 |

790 |

1460 |

2440 |

1460 |

2440 |

|

1800 |

870 |

1560 |

2650 |

1560 |

2650 |

|

2000 |

950 |

1670 |

2860 |

1670 |

2860 |

|

DN(mm) |

L |

2.5MPa |

4.0MPa |

||

|

H1 |

H |

H1 |

H |

||

|

100 |

190 |

280 |

390 |

280 |

390 |

|

125 |

200 |

300 |

420 |

300 |

420 |

|

150 |

210 |

320 |

460 |

320 |

460 |

|

200 |

230 |

370 |

550 |

370 |

550 |

|

250 |

250 |

420 |

620 |

420 |

620 |

|

300 |

270 |

500 |

750 |

500 |

750 |

|

350 |

290 |

530 |

800 |

530 |

800 |

|

400 |

310 |

570 |

870 |

570 |

870 |

|

450 |

330 |

600 |

920 |

600 |

920 |

|

500 |

350 |

680 |

1040 |

680 |

1040 |

|

600 |

390 |

750 |

1190 |

750 |

1190 |

|

700 |

430 |

810 |

1290 |

/ |

/ |

|

800 |

470 |

905 |

1440 |

/ |

/ |

|

900 |

510 |

960 |

1550 |

/ |

/ |

|

1000 |

550 |

1010 |

1650 |

/ |

/ |

|

1200 |

630 |

1175 |

1920 |

/ |

/ |

|

1400 |

710 |

/ |

/ |

/ |

/ |

|

1600 |

790 |

/ |

/ |

/ |

/ |

|

1800 |

870 |

/ |

/ |

/ |

/ |

|

2000 |

950 |

/ |

/ |

/ |

/ |

.jpg)