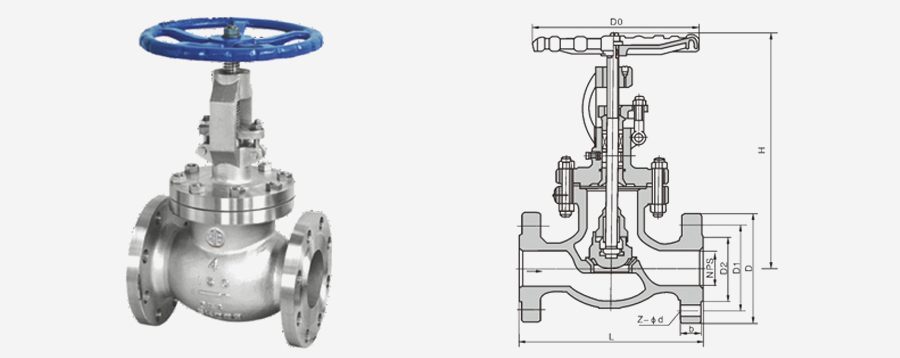

API Standard Globe Valve

Size Range: 1/2”-8”

Pressure: Class150-class600

Temperature: -29℃-425℃

Concatenon: Flange

Medium: Water,oil,steam

Body: WCB/stainless steel

Product advantages

- Simple structures.Easier to be manufactured and repaired.

- Small working stroke,short opening and closing time.

- Good sealing performance,small friction between sealing face and life long.

- The friction between sealing face is smaller than gate valve during the process of opening and closing.And it’s wear-resistant.

- It usually have only one sealing face,good manufacturing process and easy to be repaired.

- The structure style of globe valve’s body can be divided into straight-through, three-and right-angle type.

| specifications | L | D | D1 | D2 | b | n-Φd | W | H | |

| class150 | |||||||||

| 1/2” | Jum | 108 | 90 | 60.5 | 35 | 12 | 4-15 | 125 | 169 |

| in | 4.25 | 3.5 | 2.38 | 1.38 | 0.47 | 4-0.59 | 4.92 | 6.65 | |

| 3/4 | mum | 117 | 95 | 70 | 43 | 12 | 4-15 | 125 | 180 |

| in | 4.61 | 3.86 | 2.76 | 1.69 | 0.47 | 4-0.59 | 4.92 | 7.08 | |

| 1″ | mum | 127 | 108 | 79.5 | 51 | 12 | 4-15 | 125 | 190 |

| in | 5 | 4.25 | 3.13 | 2 | 0.47 | 4-0.59 | 4.92 | 7.48 | |

| 1 1/2° | mum | 165 | 127 | 98.5 | 73 | 14.3 | 4-16 | 180 | 347 |

| in | 6.5 | 5 | 3.88 | 2.87 | 0.56 | 4-0.62 | 7.09 | 13.66 | |

| 2″ | mum | 203 | 152 | 120.5 | 92 | 15.9 | 4-19 | 180 | 356 |

| in | 8 | 6 | 4.75 | 3.62 | 0.625 | 4-0.75 | 7.09 | 14 | |

| 2 1/2″ | Jum | 216 | 178 | 139.5 | 105 | 17.5 | 4-19 | 240 | 381 |

| in | 8.5 | 7 | 5.5 | 4.12 | 0.69 | 4-0.75 | 9.45 | 15 | |

| 3″ | Jum | 241 | 190 | 152.4 | 127 | 19.1 | 4-19 | 280 | 13 |

| in | 9.5 | 7.5 | 6 | 5 | 0.75 | 4-0.75 | 11.02 | 16.25 | |

| 4″ | Jum | 292 | 229 | 190.5 | 157 | 24 | 8-19 | 280 | 500 |

| in | 11.5 | 9 | 7.5 | 6.19 | 0.94 | 8-0.75 | 11.02 | 19.68 | |

| 6″ | mum | 406 | 279 | 241.5 | 216 | 25.4 | 8-22 | 360 | 656 |

| in | 16 | 11 | 9.5 | 8.5 | 1 | 8-0.88 | 14.17 | 22.25 | |

| 8° | mum | 495 | 343 | 298.5 | 270 | 29 | 8-22 | 17.75 | 660 |

| in | 19.5 | 13.5 | 11.75 | 10.62 | 1.12 | 8-0.88 | 450 | 26 | |

| class300 | |||||||||

| 1/2” | Jum | 152 | 95 | 66.5 | 35 | 15 | 4-15 | 125 | 190 |

| in | 5.98 | 3.74 | 2.62 | 1.38 | 0.95 | 4-0.59 | 4.92 | 7.84 | |

| 3/4 | Jum | 178 | 117 | 82.5 | 43 | 16 | 4-19 | 125 | 212 |

| in | 7 | 4.61 | 3.25 | 1.69 | 0.62 | 4-0.75 | 4.92 | 8.35 | |

| 1″ | mum | 203 | 124 | 89 | 51 | 18 | 4-19 | 160 | 231 |

| in | 8 | 4.9 | 3.5 | 2 | 0.71 | 4-0.75 | 6.2 | 9.1 | |

| 1 1/2″ | Jum | 229 | 156 | 114.5 | 73 | 20.7 | 4-22 | 200 | 391 |

| in | 9 | 6.12 | 4.51 | 2.87 | 0.81 | 4-0.87 | 8 | 15.43 | |

| 2” | Jum | 267 | 165 | 127 | 92 | 22 | 8-19 | 200 | 406 |

| in | 10.5 | 6.5 | 5 | 3.62 | 0.88 | 8-0.75 | 7.87 | 16 | |

| 2 1/2 | mum | 292 | 190 | 149 | 105 | 25 | 8-22 | 240 | 457 |

| in | 11.5 | 7.5 | 5.88 | 4.12 | 1 | 8-0.88 | 9.45 | 18 | |

| 3′ | Jum | 318 | 210 | 168.5 | 127 | 29 | 8-22 | 280 | 470 |

| in | 1250 | 8.25 | 6.62 | 5 | 1.12 | 8-0.88 | 11.02 | 18.5 | |

| 4 | Jum | 356 | 245 | 200 | 157 | 32 | 8-22 | 320 | 590 |

| in | 14 | 10 | 7.88 | 6.19 | 1.25 | 8-0.88 | 12.6 | 23.23 | |

| 6° | Jum | 444 | 318 | 270 | 216 | 37 | 12-22 | 500 | 711 |

| in | 17.5 | 12.5 | 1062 | 8.5 | 1.44 | 12-0.88 | 19.68 | 28 | |

| 8° | Jum | 559 | 381 | 330 | 270 | 41 | 12-25 | 500 | 750 |

| in | 22 | 15 | 13 | 10.62 | 1.62 | 12-100 | 19.68 | 29.5 | |

| class600 | |||||||||

| 1/2″ | mum | 165 | 95 | 66.5 | 35 | 15 | 4-15 | 160 | 285 |

| in | 6.5 | 3.74 | 2.62 | 1.38 | 0.59 | 4-0.59 | 6.2 | 11.22 | |

| 3/4” | Jum | 190 | 117.5 | 82.5 | 43 | 16 | 4-19 | 160 | 285 |

| in | 7.48 | 4.61 | 3.25 | 1.69 | 0.62 | 4-0.75 | 6.2 | 11.22 | |

| 1″ | mum | 216 | 124 | 89 | 2 | 18 | 4-19 | 160 | 313 |

| in | 8.5 | 4.9 | 3.5 | 73 | 0.71 | 4-0.75 | 6.2 | 12.32 | |

| 1 1/2″ | Jum | 241 | 156 | 114.5 | 51 | 23 | 4-22 | 240 | 365 |

| in | 9.5 | 6.12 | 4.51 | 92 | 0.91 | 4-0.87 | 9.45 | 14.17 | |

| 2” | Jum | 292 | 165 | 127 | 2.87 | 25 | 8-19 | 240 | 444 |

| in | 11.5 | 6.5 | 5 | 105 | 1 | 8-0.75 | 9.45 | 17.5 | |

| 2 1/2″ | mum | 330 | 190 | 149 | 127 | 29 | 8-22 | 240 | 483 |

| in | 18 | 7.5 | 5.88 | 5 | 1.12 | 8-0.88 | 9.45 | 19 | |

| 3″ | mum | 358 | 210 | 168 | 3.62 | 32 | 8-22 | 280 | 533 |

| in | 14 | 8.25 | 6.62 | 157 | 1.25 | 8-0.88 | 11.02 | 21 | |

| 4” | Jum | 4.06 | 273 | 216 | 216 | 38.1 | 8-25 | 360 | 622 |

| in | 16 | 10.75 | 8.5 | 4.12 | 1.5 | 8-19 | 14.17 | 24.5 | |

| 6 | mum | 459 | 356 | 292 | 8.5 | 47.7 | 12-29 | 500 | 800 |

| in | 19.5 | 14 | 11.5 | 270 | 1.88 | 12-1.14 | 19.68 | 31.5 | |

| 8° | Jum | 597 | 419 | 34.9 | 6.19 | 55.6 | 12-32 | 550 | 927 |

| in | 23.5 | 16.5 | 13.75 | 10.62 | 2.19 | 12-1.25 | 21.65 | 36.5 | |

.jpg)

.jpg)

.jpg)