DN3000 Double Eccentric Butterfly Valve

Size Range: DN50-DN4000

Pressure: PN6/10/16/25/40 Mpa 150/300 Class

Body Materials: Ductile Iron、Carbon Steel、Stainless Steel、Duplex Steel

Seat Materials: EPDM/PTFE

Disc Seat Ring: NBR、EPDM、PTFE

Shaft: Austenitic stainless steel、Martensitic stainless steel、Duplex steel、Super duplex steel

Disc: Ductile Iron、Carbon Steel、Stainless Steel、Duplex Steel

Applicable medium: Air,water,sea water,sewage,gas,oil,etc.

Proper temperature: -29℃~120℃;-29℃~425℃

Drive mode: Worm gear、pneumatic、hydraulic、electric

(1). Valve opening and closing torque is small

Due to the existence of eccentricity, when the valve is closed, the sealing surface is a process of gradually entering and exiting, thus reducing the mechanical wear and extrusion between the sealing surfaces.

(2). Sealing specific pressure can be adjusted

When the valve is used for a period of time or loosened during transportation, it can be pressurized to ensure the sealing requirements.

(3). Seals are field replaceable

The rubber sealing ring is installed on the butterfly plate and can be replaced online.

(4). long lasting

The contact between the sealing ring and the valve seat is a coincident seal, and there is no mechanical wear and extrusion, so the sealing ring of the double eccentric butterfly valve has a long service life.

(5). Conditions of Use

It is suitable for large-scale installations and pipelines in drainage, heating, gas systems, chemical power generation, metallurgy and other industries.

(6). With two-way sealing performance With two-way

Sealing performance, especially suitable for working conditions where the medium requires both forward flow and reverse flow (please specify when ordering).

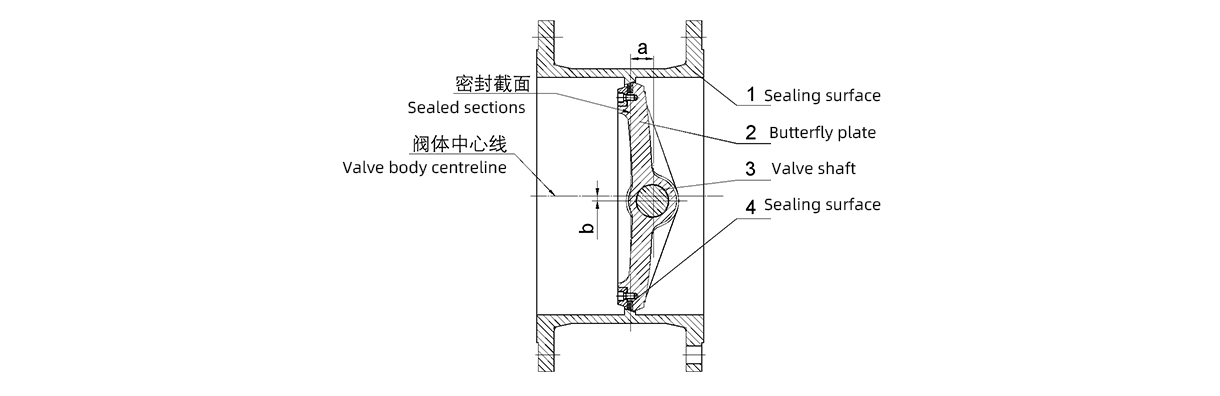

Double eccentric design principle and characteristics

The butterfly valve has a double eccentric soft seal structure, that is, the eccentric distance from the center of rotation of the butterfly plate to the sealing section a of the valve body, and the distance from the center of rotation of the butterfly plate to the center line of the valve body b, (see the figure below). The valve adopts worm gear transmission deceleration (electric valve is decelerated by motor through worm gear transmission), and the valve shaft drives the butterfly plate to rotate within 90°C, so that the butterfly plate is in the open or closed state to achieve the purpose of connecting or cutting off the medium. As shown in the figure, when the valve is closed, the sealing ring is squeezed by the sealing surface of the valve body and the butterfly plate, resulting in deformation.

Features of double eccentric butterfly valve:

(1) It has two-way sealing performance, especially suitable for the working conditions where the medium has both forward flow requirements and reverse flow requirements (please specify when ordering);

(2) Double eccentric sealing structure is adopted, which has the function of getting tighter and tighter when closing, and the sealing performance is reliable.

(3) The butterfly plate adopts a streamlined structure with high strength, large flow area and small flow resistance;

(4) Change the material of the valve body, the sealing ring is located on the butterfly plate, and the material of the sealing ring can be changed to apply to different media;

(5) The worm gear drive is fully enclosed and flexible in operation.

(6) The electrical device is an imported integrated product, which can be controlled locally or remotely, and the control is safe and reliable.

.jpg)

| Size | Outline dimensions | Flange dimensions EN1092-2 | |||||||||||||||

| DN | L | H1 | H2 | PN6 | PN10 | PN16 | |||||||||||

| Inch | mm | Series13 | Series14 | D | K | b | n-Φd | D | K | b | n-Φd | D | K | b | n-Φd | ||

| 2 | 50 | 108 | 150 | 83 | 306 | 140 | 110 | 16 | 4-14 | 165 | 125 | 19 | 4-19 | 165 | 125 | 19 | 4-19 |

| 2-1/2 | 65 | 112 | 170 | 93 | 321 | 160 | 130 | 16 | 4-14 | 185 | 145 | 19 | 4-19 | 185 | 145 | 19 | 4-19 |

| 3 | 80 | 114 | 180 | 100 | 346 | 190 | 150 | 18 | 4-19 | 200 | 160 | 19 | 8-19 | 200 | 160 | 19 | 4-19 |

| 4 | 100 | 127 | 190 | 110 | 387 | 210 | 170 | 18 | 4-19 | 220 | 180 | 19 | 8-19 | 220 | 180 | 19 | 8-19 |

| 5 | 125 | 140 | 200 | 125 | 411 | 240 | 200 | 20 | 8-19 | 250 | 210 | 19 | 8-19 | 250 | 210 | 19 | 8-19 |

| 6 | 150 | 140 | 210 | 143 | 447 | 265 | 225 | 20 | 8-19 | 285 | 240 | 19 | 8-23 | 285 | 240 | 19 | 8-23 |

| 8 | 200 | 152 | 230 | 170 | 607 | 320 | 280 | 22 | 8-19 | 340 | 295 | 20 | 8-23 | 340 | 295 | 20 | 12-23 |

| 10 | 250 | 165 | 250 | 193 | 688 | 375 | 335 | 24 | 12-19 | 395 | 350 | 22 | 12-23 | 405 | 355 | 22 | 12-28 |

| 12 | 300 | 178 | 270 | 223 | 742 | 440 | 395 | 24 | 12-23 | 445 | 400 | 24.5 | 12-23 | 460 | 410 | 24.5 | 12-28 |

| 14 | 350 | 190 | 290 | 253 | 797 | 490 | 445 | 26 | 12-23 | 505 | 460 | 24.5 | 16-23 | 520 | 470 | 26.5 | 16-28 |

| 16 | 400 | 216 | 310 | 283 | 930 | 540 | 495 | 28 | 16-23 | 565 | 515 | 24.5 | 16-28 | 580 | 525 | 28 | 16-31 |

| 18 | 450 | 222 | 330 | 308 | 975 | 595 | 550 | 28 | 16-23 | 615 | 565 | 25.5 | 20-28 | 640 | 585 | 30 | 20-31 |

| 20 | 500 | 229 | 350 | 335 | 1065 | 645 | 600 | 30 | 20-23 | 670 | 620 | 26.5 | 20-28 | 715 | 650 | 31.5 | 20-34 |

| 24 | 600 | 267 | 390 | 390 | 1225 | 755 | 705 | 30 | 20-26 | 780 | 725 | 30 | 20-31 | 840 | 770 | 36 | 20-37 |

| 28 | 700 | 292 | 430 | 448 | 1343 | 860 | 810 | 32 | 24-26 | 895 | 840 | 32.5 | 24-31 | 910 | 840 | 39.5 | 24-37 |

| 32 | 800 | 318 | 470 | 508 | 1463 | 975 | 920 | 34 | 24-31 | 1015 | 950 | 35 | 24-34 | 1025 | 950 | 43 | 24-40 |

| 36 | 900 | 330 | 510 | 558 | 1616 | 1075 | 1020 | 36 | 24-31 | 1115 | 1050 | 37.5 | 28-34 | 1125 | 1050 | 46.5 | 28-40 |

| 40 | 1000 | 410 | 550 | 615 | 1711 | 1175 | 1120 | 36 | 28-31 | 1230 | 1160 | 40 | 28-37 | 1255 | 1170 | 50 | 28-43 |

| 48 | 1200 | 470 | 630 | 728 | 1971 | 1405 | 1340 | 40 | 32-34 | 1455 | 1380 | 45 | 32-40 | 1485 | 1390 | 57 | 32-49 |

| 56 | 1400 | 530 | 710 | 838 | 2218 | 1630 | 1560 | 44 | 36-37 | 1675 | 1590 | 46 | 36-43 | 1685 | 1590 | 60 | 36-49 |

| 64 | 1600 | 600 | 790 | 958 | 2578 | 1830 | 1760 | 48 | 40-37 | 1915 | 1820 | 49 | 40-49 | 1930 | 1820 | 65 | 40-56 |

| 72 | 1800 | 670 | 870 | 1058 | 2689 | 2045 | 1970 | 50 | 44-40 | 2115 | 2020 | 52 | 44-49 | 2130 | 2020 | 70 | 44-56 |

| 80 | 2000 | 760 | 950 | 1163 | 3022 | 2265 | 2180 | 54 | 48-43 | 2325 | 2230 | 55 | 48-49 | 2345 | 2230 | 75 | 48-62 |

| 88 | 2200 | 800 | 1000 | 1163 | 3022 | 2265 | 2180 | 54 | 48-43 | 2325 | 2230 | 55 | 48-49 | 2345 | 2230 | 75 | 48-62 |

| 96 | 2400 | 850 | 1100 | 1163 | 3022 | 2265 | 2180 | 54 | 48-43 | 2325 | 2230 | 55 | 48-49 | 2345 | 2230 | 75 | 48-62 |

| 104 | 2600 | 900 | 1200 | 1163 | 3022 | 2265 | 2180 | 54 | 48-43 | 2325 | 2230 | 55 | 48-49 | 2345 | 2230 | 75 | 48-62 |

| 112 | 2800 | 950 | 1300 | 1163 | 3022 | 2265 | 2180 | 54 | 48-43 | 2325 | 2230 | 55 | 48-49 | 2345 | 2230 | 75 | 48-62 |

| 120 | 3000 | 1000 | 1400 | 1163 | 3022 | 2265 | 2180 | 54 | 48-43 | 2325 | 2230 | 55 | 48-49 | 2345 | 2230 | 75 | 48-62 |

.jpg)

.jpg)