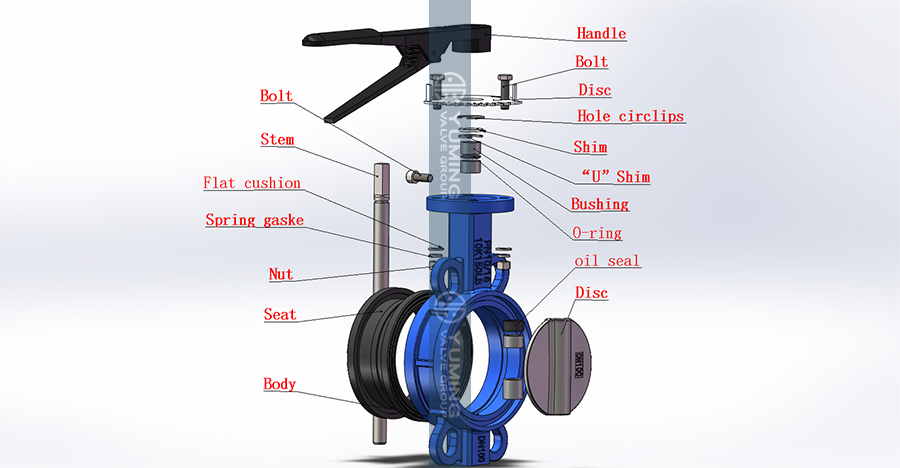

Wafer Soft Seal Butterfly Valve

Size Range: 2“-100”(DN50-DN2500)

Pressure: PN10,PN16,Class150

Body Materials: Ductile Iron/ WCB/CF8/CF8M

Disc Materials: Ductile Iron/ WCB/CF8/CF8M

Seat Materials: NBR, EPDM,PTFE

Connection: Wafer

Application fields: Municipal construction, water treatment, water supply and drainage, water conservancy projects, etc.

- All products can provide the pressure test: All Yuming products can provide the pressure test report before leaving the factory.

- High performance seat rubber: The rubber content is 50%, and the switch life is more than 30000 times

- Soft seat: Compared with the hard seat, the contact surface between pipes and flanges is more wider than hard seat, and sealing performance of installation is better, and the special flange of the butterfly valve is not required;

- Axial seal: The shaft is supported by 4 oil-free bearings, with o-ring and oil seal double seal structure design, smaller torque and reliable seal;

- Surface coating: Epoxy powder coating is adopted, with strong adhesion and good weather resistance. It can be used indoors and outdoors.

- Ductile iron handle: The handle is made of ductile iron, compared with Stamping handle, ductile iron handle is more better strength, stronger corrosion resistance and much more durable. The end handle with half-round structure design, is no edges and corners and feels very good.

- The design of shaft is blow-off resistant: The no-pin butterfly valve is designed with anti blow-off structure, and handle can be changed under pressure.

Design and manufacturing standards: GB/T 12238

Structure length standard: GB/T 12221

Test standard: GB/T 13927

Upper flange connection standard: ISO 5211

Flange size standard: GB/T 17241.6, ASME B16.5, ASME B16.47,

ASME B16.1, JIS B2220

Material of main parts

Body material: DI

Butterfly plate material: DI, CF8, CF8M, CF3, CF3M, 1.4529, C594, C598

Seat material: EPDM, NBR, Viton

Valve shaft material: SS416, SS420, SS304

.jpg)

| DN | A | D1 | L1 | L2 | L3 | B | φD2 | φD3 | n-φd | L | |

| 1.5″ | DN40 | 34 | 62.5 | 55.5 | 111.5 | 25 | 9 | 65 | 50 | 4-8 | 249 |

| 2″ | DN50 | 43 | 80 | 72 | 132 | 25 | 9 | 65 | 50 | 4-8 | 249 |

| 2.5″ | DN65 | 46 | 95 | 86 | 138 | 25 | 9 | 65 | 50 | 4-8 | 249 |

| 3″ | DN80 | 46 | 113 | 96 | 153 | 25 | 9 | 65 | 50 | 4-8 | 249 |

| 4″ | DN100 | 52 | 135 | 108 | 167 | 28 | 11 | 90 | 70 | 4-10 | 283 |

| 5″ | DN125 | 56 | 163 | 125 | 184 | 28 | 14 | 90 | 70 | 4-10 | 283 |

| 6″ | DN150 | 56 | 190 | 138 | 195 | 28 | 14 | 90 | 70 | 4-10 | 283 |

| 8″ | DN200 | 60 | 244 | 170 | 236 | 33 | 17 | 125 | 102 | 4-12 | 390 |

| 10″ | DN250 | 68 | 298 | 209 | 266 | 33 | 22 | 125 | 102 | 4-12 | 390 |

| 12″ | DN300 | 78 | 350 | 236 | 305 | 33 | 22 | 125 | 102 | 4-12 | 540 |

.jpg)