What is a Globe Valve?

A globe valve is a type of valve used to regulate the flow of liquids or gases in a piping system. It features a distinctive design with a spherical disc and an adjustable orifice to control the flow. When the valve is open, the spherical disc moves up or down within the valve body to create an opening through which fluid or gas can pass.

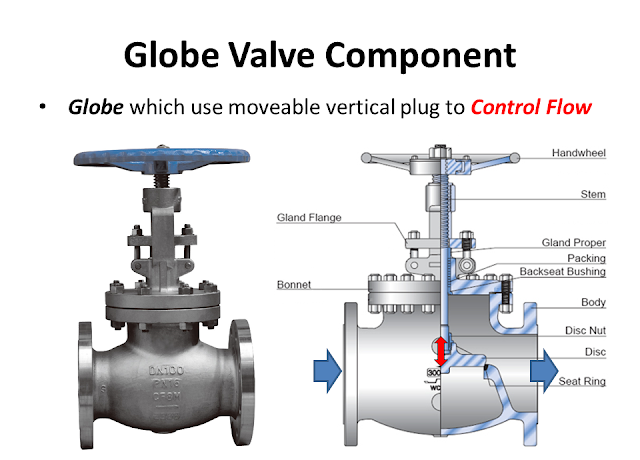

Components of a Globe Valve

A globe valve typically consists of the following main components:

- Body: The outer casing of the valve that houses the internal parts. The body is usually made from materials such as steel, brass, or plastic.

- Spherical Disc (Disc): The main internal component that moves to adjust the size of the opening. The disc helps control the flow and pressure of the fluid or gas.

- Stem: Connects the spherical disc to the handwheel or actuator, allowing the disc to be raised or lowered.

- Handwheel or Actuator: Used to control the movement of the spherical disc up or down.

- Seals and Gaskets: Ensure that when the valve is closed, no fluid or gas leaks out.

Working Principle

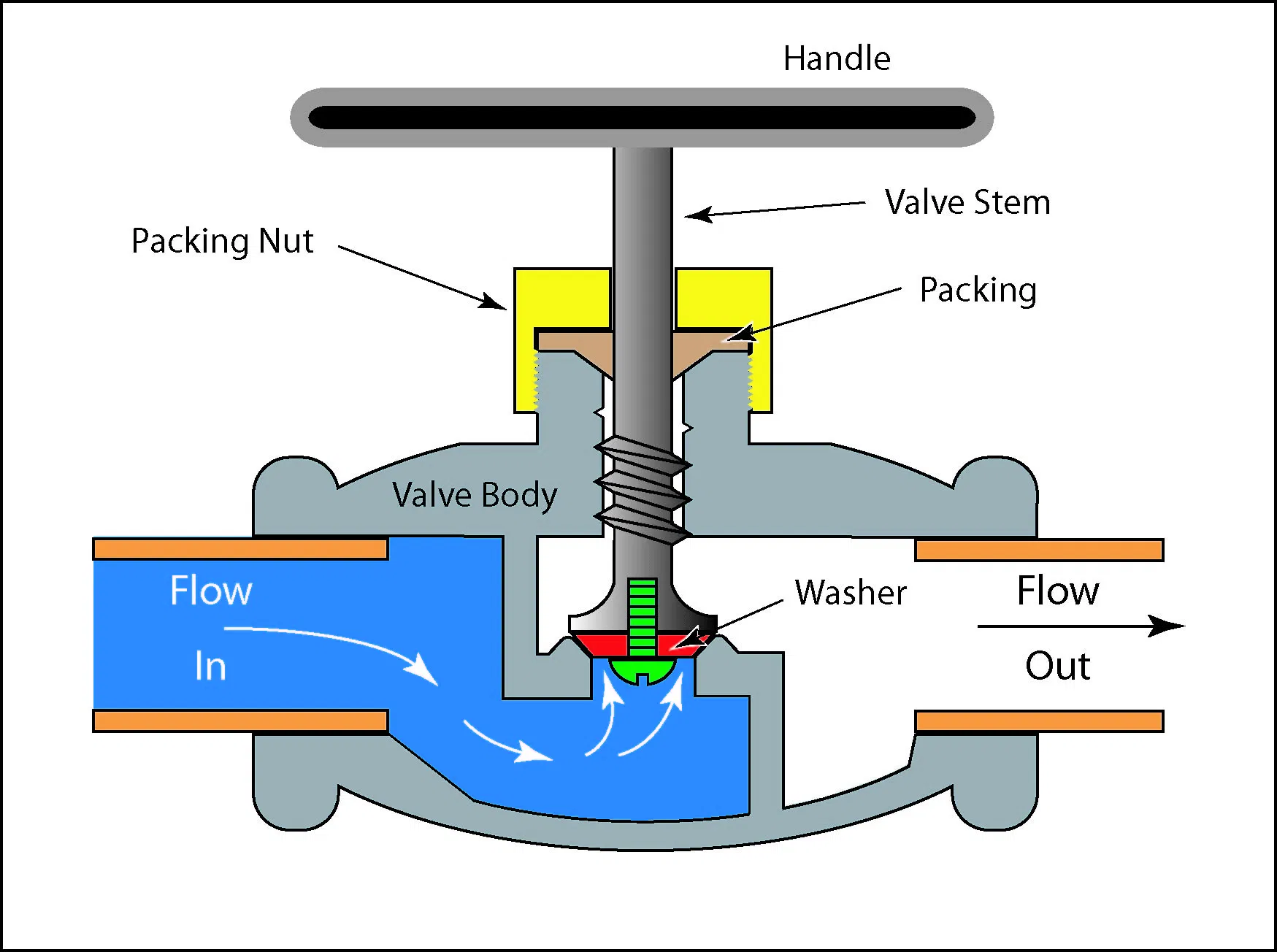

The working principle of a globe valve is as follows:

- When Open: The handwheel or actuator is used to lift the spherical disc, creating an opening that allows fluid or gas to flow through.

- When Closed: The handwheel or actuator lowers the spherical disc to reduce or close off the opening, blocking the flow.

Advantages of Globe Valves

Globe valves offer several benefits, including:

- Precise Flow Control: Allows for accurate adjustment of the flow rate of fluids or gases.

- High Performance: Provides good pressure and flow control, suitable for applications requiring precise regulation.

- Tight Sealing: Can be closed completely when necessary, effectively preventing leaks.

- Durability: Designed to be robust and typically has a long service life.

Applications of Globe Valves

Globe valves are used in a variety of industries and applications, such as:

- Water Supply Systems: To regulate the flow of water in piping systems.

- Chemical Industry: To control the flow of chemicals in processing operations.

- Power Generation: To adjust cooling water flow and other systems in power plants.

- Oil and Gas Industry: To control and regulate the flow of oil and gas.

Conclusion

Globe valves are essential components in many piping systems due to their ability to provide precise flow control and effective performance. With their unique design and capability for accurate regulation, globe valves play a crucial role in managing and controlling the flow of liquids and gases in various industrial and domestic applications. Choosing the right globe valve can enhance the performance and reliability of your piping system.