Corrosion Protection

Metal surfaces need adequate protection – that’s a common fact for decades.

Many different anti-corrosion products and galvanical processes on the market claim “to have a leading” protection position. However the user is pretty much left alone with a confusing number of possible materials and even more so when it comes to their correct application.

Having a closer look at the real technical requirements things become a little bit easier. Most requisitions cover a static anti-corrosion demand which paints or galvanic treatments can easily handle. On the other hand a remaining part requires dynamic protection qualities! In addition to the basic anti-corrosion demand, mechanical forces exist overexceeding common solutions. Impact, wear or immersion conditions require simply more. That’s where synthetic elastomeric coatings jump in with its enhanced heavy-duty corrosion protection properties.

Corroded surface

Technical solutions in detail

Polymeric linings cartridge spraying process is based on a novel packaging and application technology. The material is delivered ready for spraying in an airtight double-cartridge. It is only necessary to screw on the static mixer/spray-nozzle supplied. Using the Polymeric linings, the cartridge’s content are uniformly pressed into the static mixer, mixed thoroughly and sprayed on with air atomized through the nozzle attachement.

- Atomizing is similar to spray gun painting, however, it is possible to apply far greater quantities and achieve considerably higher film thicknesses.

- Polymeric linings react very quickly and already 1 minute after application the material stops flowing. Owing to this, it is possible to achieve enormous film thicknesses quickly and uniformly – even on vertical surfaces or overhead.

- The cartridge’s content is not making any contact with the Polymeric linings at all, as it is sprayed off directly from the packaging not traveling through the spray tool. None whatsoever equipment cleaning is requried! The one-way static mixer will be disposed of after processing. Cartridges not used up completely can be removed and reused at a later stage.

- Polymeric linings materials do not contain any solvents or water! They do not pose any hazard to the user during processing or curing. Nonetheless, they have to be processed in areas equipped with a suitable extraction system and respiratory masks are prescribed for the user.

- Owing to its durability, swiftness, and cleanliness, the Polymeric linings concept has gained a leading position in international surface protection. Preparing the substrate thoroughly beforehand is an absolute must! Handling requires know-how and initial training is mandatory!

Description

60 Shore A (soft)

High stiction

FDA compliant

Application

For rubber repairs with the scope of applications bellow:

- Wear protection

- Cavitation protection

- Corrosion protection

- Electrical / thermal insulation

- Liquid sealing

- Noise deadening

- Castings / injections

- Impact protection

Description

85 Shore A (medium-soft)

Medium stiction

FDA compliant

Application

For wear protection with the scope of applications bellow:

- Wear protection

- Cavitation protection

- Corrosion protection

- Electrical / thermal insulation

- Liquid sealing

- Noise deadening

- Castings / injections

- Impact protection

Description

95 Shore A (semi-hard)

low stiction

FDA compliant

Application

For non-stick coatings with the scope of applications bellow:

- Non-stick linings

- Glide optimization

- Corrosion protection

- Electrical / thermal insulation

- Liquid sealing

- Noise deadening

- Castings / injections

- Scratch / marking protection

Scope of application

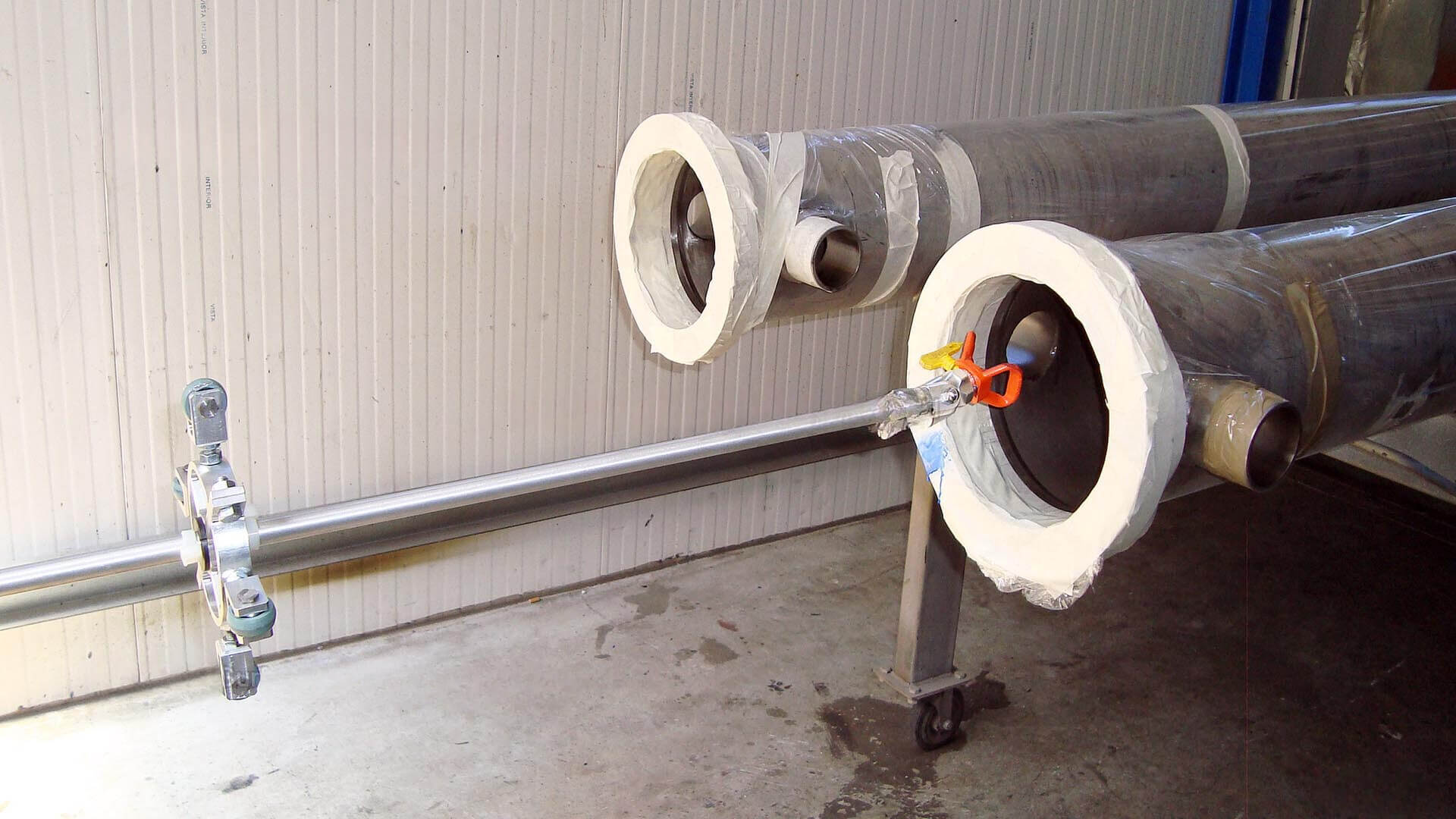

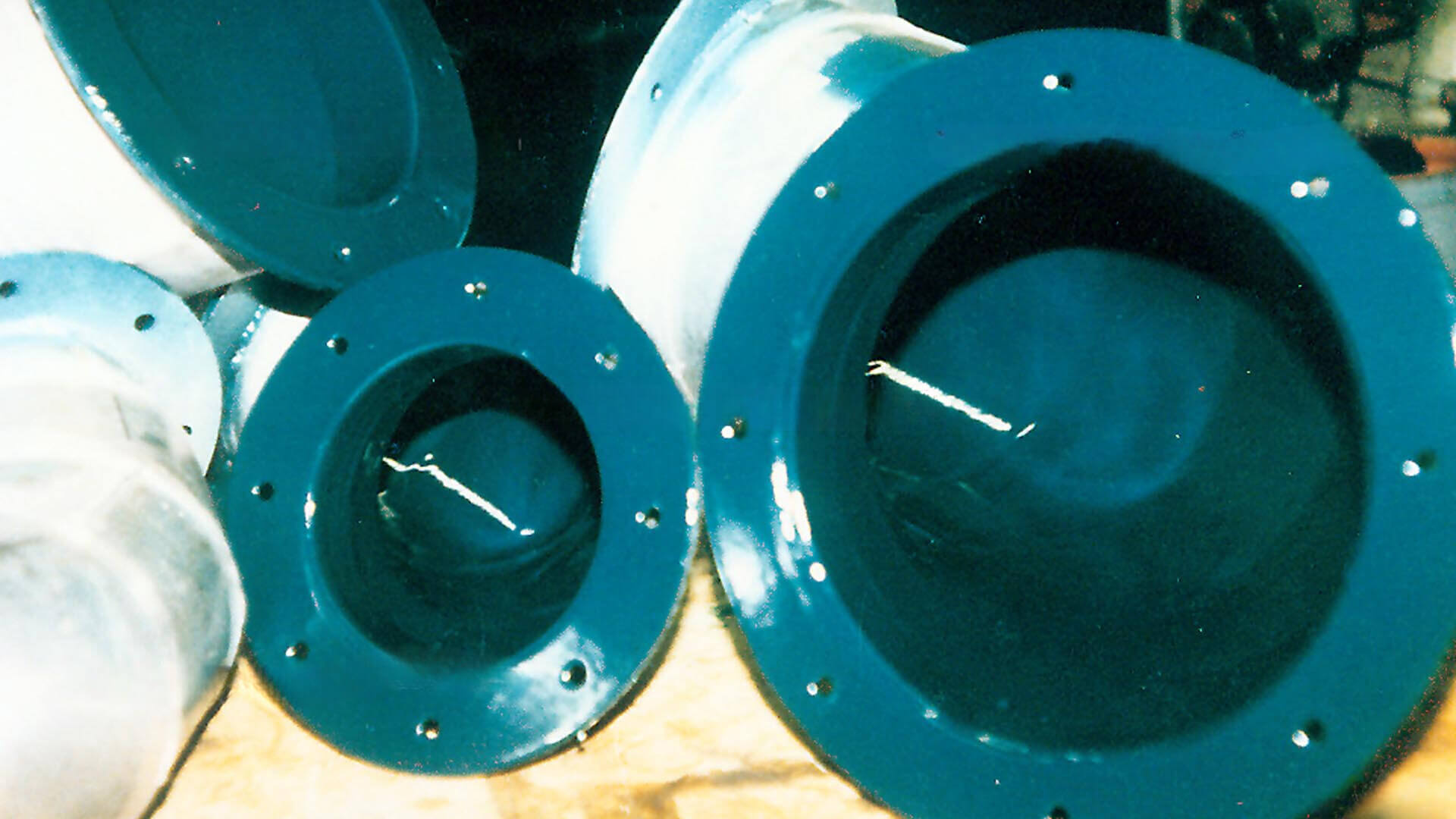

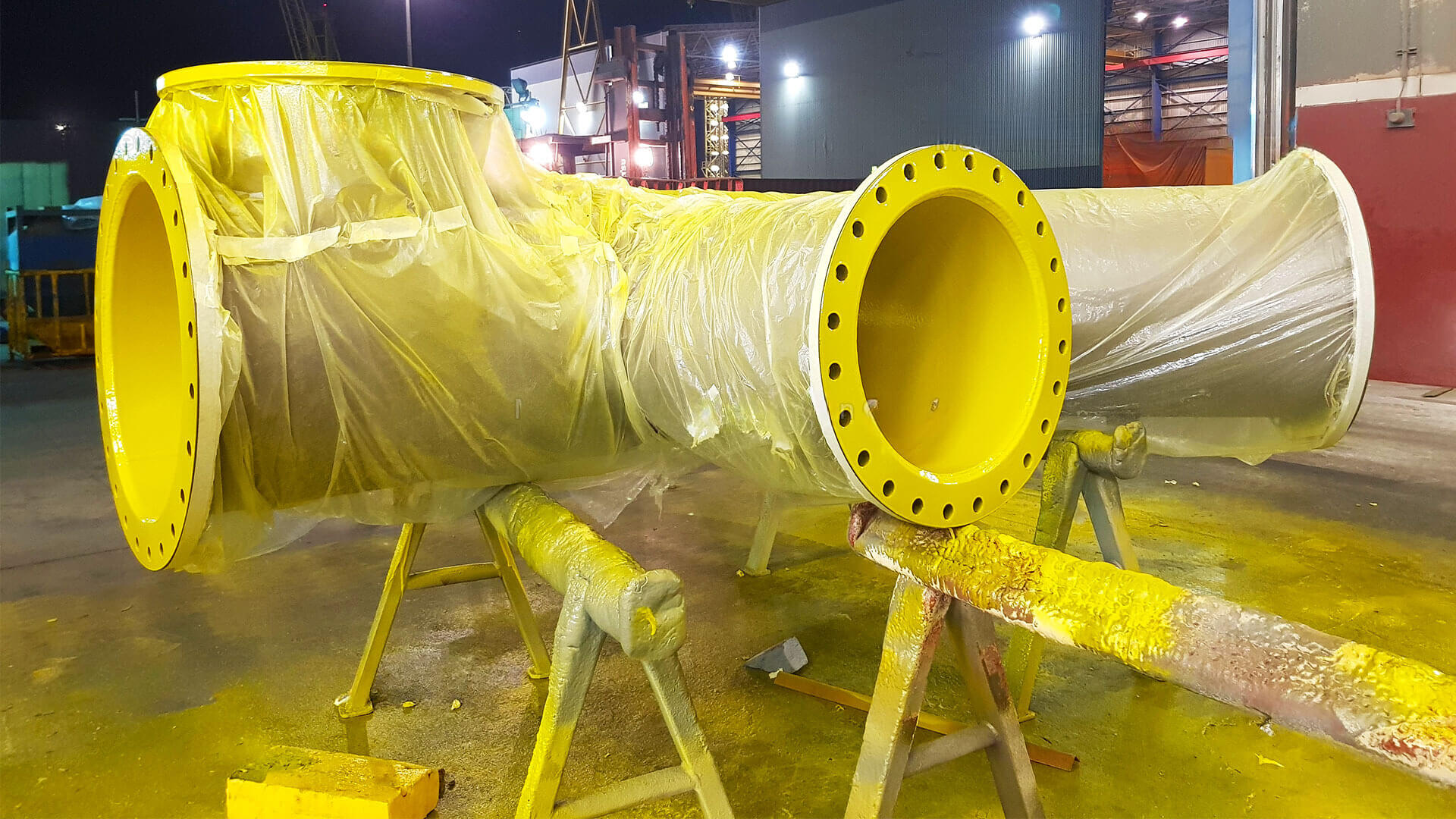

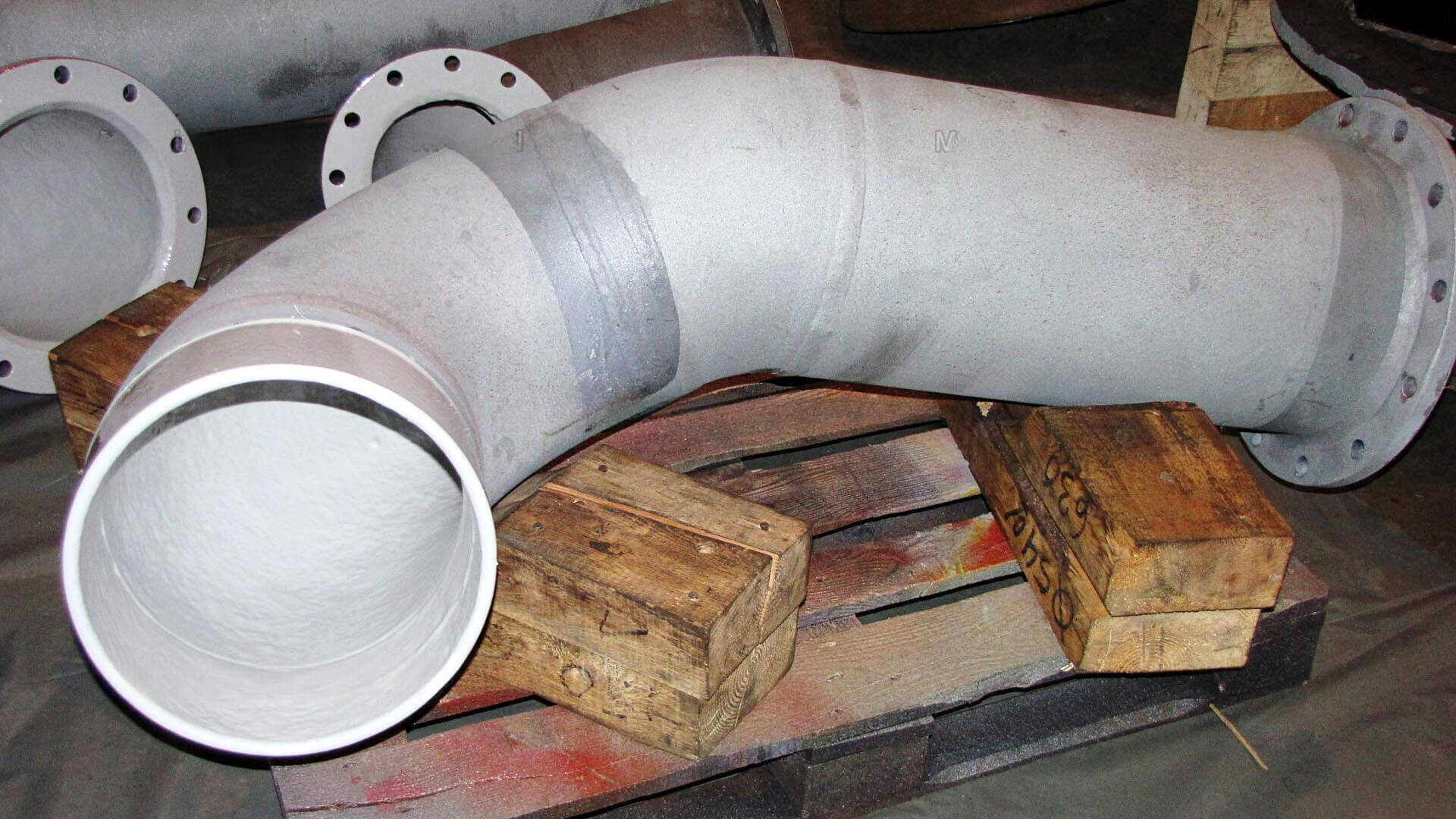

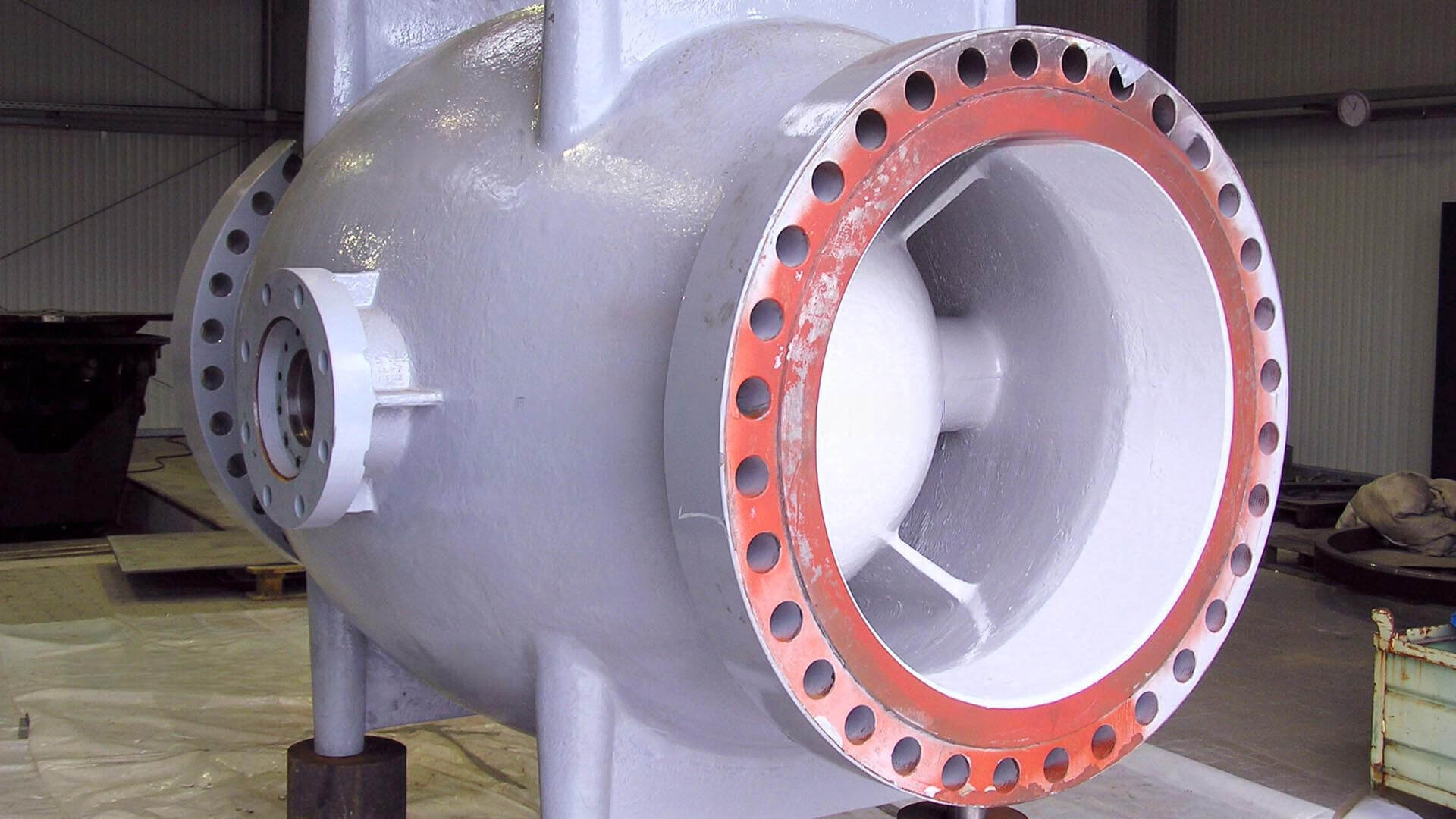

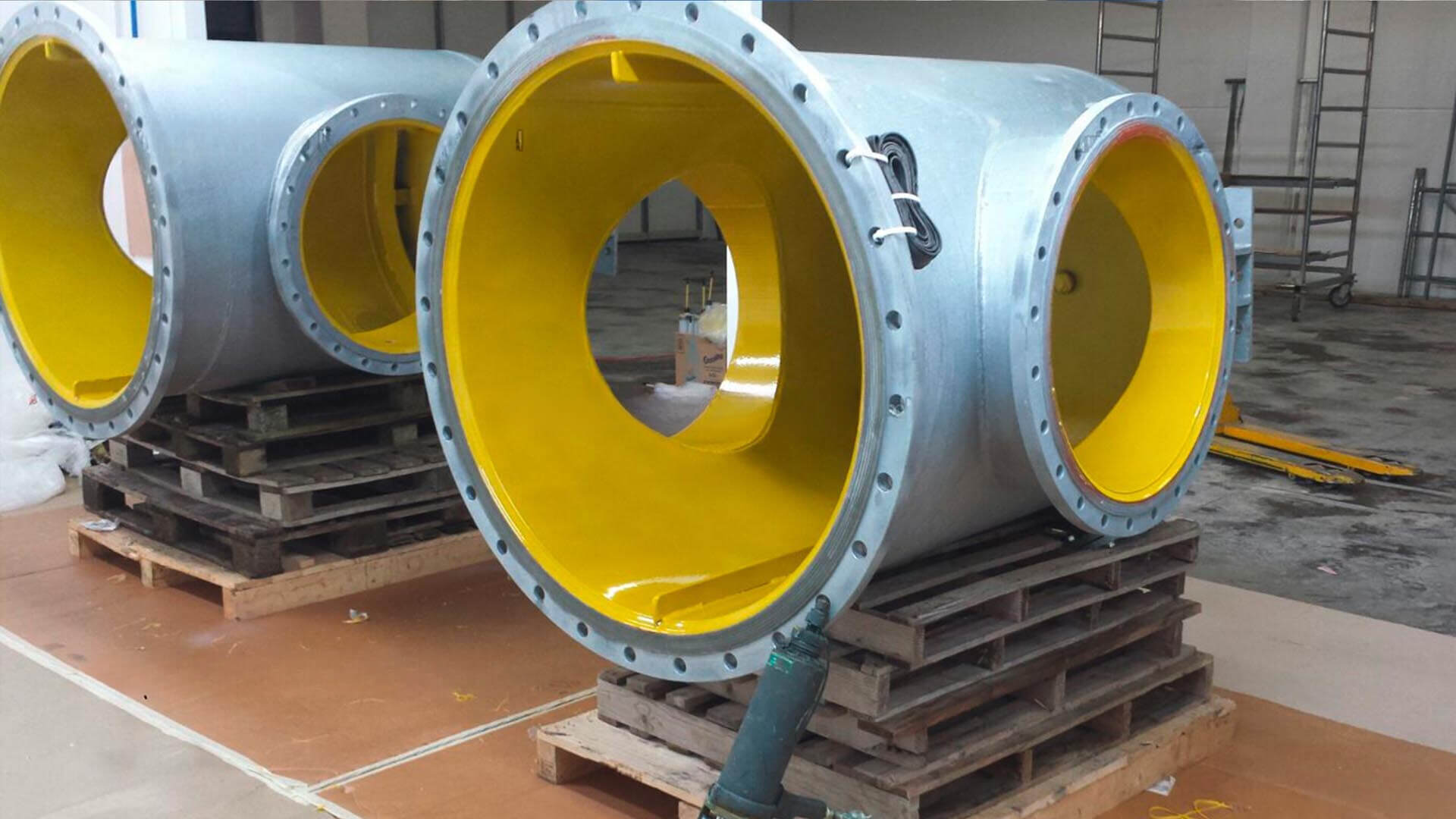

Corrosion protection for Seawater systems:

- Seawater pipe and elbow

- Filter/ Strainers/ Water treatment

- Body inside of Butterfly/Gate valves

- Heat Exchangers